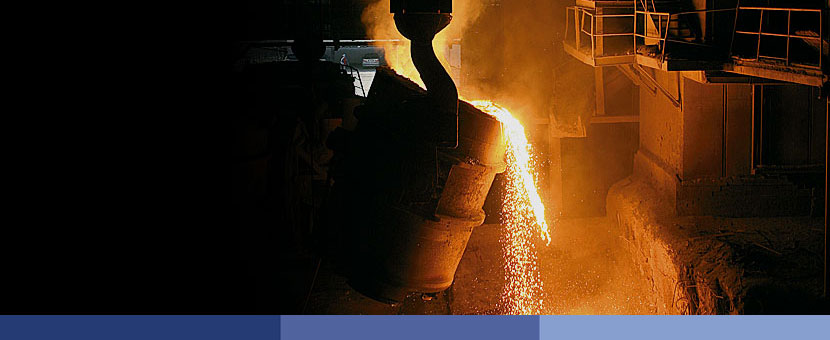

MPC Industrietechnik GmbH specialises in the manufacture of heat- and wear-resistant cast steel products. MPC products are used wherever materials are subject to high stress.

In the field of power plant technology our main focus is on steam generators, MPC produced and installed spare parts such as grate bars for travelling grates, air nozzles for fluidised bed combustion plus other high quality heat- and wear-resistant cast components to ensure your maintenances are completed quickly and at reasonable expense.

| Air nozzles |

| Protective shells |

| Immersion tubes |

MPC Industrietechnik GmbH supplies hardwearing cast components for waste incineration plant furnaces, air- and water-cooled grate bars made of heat-resistant materials, panels, side walls and other cast components for combustion grates. We have over 25 years experience in the trade.

| Grate bars |

| Front panels |

| Side walls |

| Guide beams |

| Roof components |

| Table liner segments |

| Armoured plates |

| Beaters |

| Beater strips |

| Anvils |

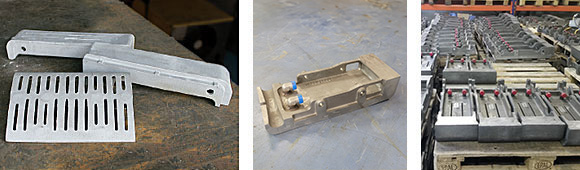

The handling of bulk goods on conveyor systems exposes carriers, scrapers and drag links to high wear and tear. That means these components must be manufactured to a high quality.

MPC has specialised in the casting and forging of parts subject to wear and tear for many years and we ensure your conveyor systems run reliably over the long term.

| Scraper |

| Fork link chains |

| Components for roller grates |

| Carriers |